All S-Box™ Chameleon models pop-up countertop units are installed at exactly 20mm below the surface on a rebate or ‘shelf’. This enables the S-Box™ to be disguised in its location and deploy its full CHAMELEON skills!

In worktop material of 30mm thickness and above, the installation is achieved by sitting the unit on a TRUE REBATE. This is cut WITHIN the material itself.

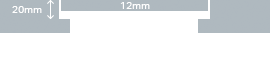

For material of 20mm thickness, or less, installation is achieved by sitting the unit as a “FALSE” REBATE. This is created by using a second/slave material immediately below.

NOTE: If worktop material is only 12mm thick (e.g. Silestone, Corian, Hi-Macs, Dekton etc) and a ‘chameleon’ installation is desired, this will need to be built up to create sufficient thickness for a rebate at -20mm to exist. SEE INSTALLATION GUIDE